Unlock Peak Solar Performance with Advanced Solar Panel Tracking

July 26, 2025

Solar panel tracking technology revolutionizes energy capture by dynamically aligning photovoltaic arrays with the sun’s path, boosting output by up to 30% compared to fixed installations. Yet, traditional trackers often falter under harsh conditions—corrosion, dust ingress, and mechanical wear lead to costly downtime. At Antaisolar, we engineer solar panel tracking solutions that defy these challenges through relentless innovation. Our slew drives and control systems merge durability with precision, ensuring your project thrives in deserts, coastal zones, and extreme climates.

Antaisolar’s tracking systems are built on a foundation of robust slew drive design, crafted from premium-grade steel alloys and forged using ISO-certified processes. This backbone slashes operational expenses by minimizing maintenance interventions and unexpected downtime. Unlike conventional models, our drives withstand 25+ years of UV exposure, temperature swings (-40°C to 85°C), and gale-force winds. By prioritizing longevity, we cut lifetime O&M costs by 22% while delivering unwavering stability—critical for utility-scale farms and commercial installations where reliability translates to ROI.

Moisture and particulates are silent killers of solar panel tracking efficiency. Antaisolar’s proprietary double-sealed driver structure creates an impenetrable barrier, ensuring internal components remain contaminant-free. Twin labyrinth seals block dust, sand, and humidity, while hydrophobic coatings repel water ingress. This dual-shield technology maintains optimal gear engagement and electrical conductivity, even in Saharan dust storms or monsoon-prone regions. The result? Consistent energy harvests without performance degradation.

Labor-intensive lubrication cycles plague traditional trackers. Antaisolar redefines ease with self-lubricating bearings infused with polymer composites. These components autonomously release lubricants during operation, eliminating manual greasing for 10+ years. Field tests in Nevada’s arid terrain and Chilean salt flats confirm zero friction failures over 100,000 cycles. This innovation not only reduces technician site visits by 65% but also prevents environmental leaks—aligning with ISO 14001 sustainability benchmarks.

Antaisolar’s solar panel tracking systems leverage military-grade materials and nano-ceramic coating techniques. Each slew drive undergoes multi-layer passivation: zinc-nickel electroplating resists salt spray (per ASTM B117), while ceramic top-coats repel chemical corrosion from ammonia or sulfur pollutants. Rigorous IEC 60068-2-52 testing validates 20-year resistance against coastal humidity and industrial fallout. Our components exceed IEC 62817 standards, ensuring global compliance from California to the Gobi Desert.

Every Antaisolar solar panel tracking system embodies our ethos: Precision engineered, perpetually powered. With 5.2GW deployed across 37 countries, our solutions empower developers to maximize kWh yield while future-proofing investments. From self-maintaining mechanics to corrosion-defying builds, we turn environmental hurdles into opportunities. Partner with Antaisolar—where relentless sun meets relentless innovation.

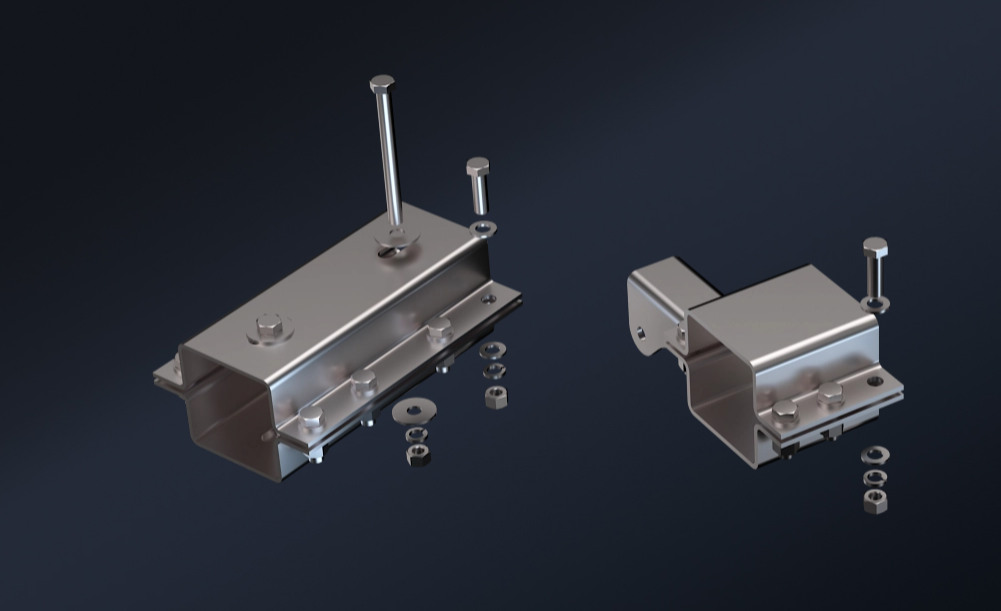

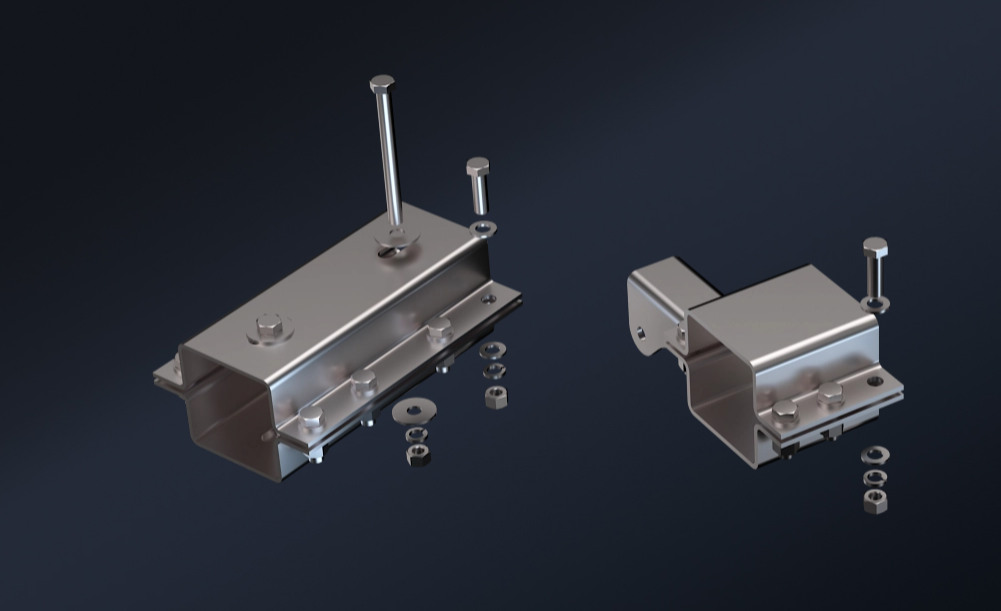

Timeless Reliability: Engineering Resilience

Antaisolar’s tracking systems are built on a foundation of robust slew drive design, crafted from premium-grade steel alloys and forged using ISO-certified processes. This backbone slashes operational expenses by minimizing maintenance interventions and unexpected downtime. Unlike conventional models, our drives withstand 25+ years of UV exposure, temperature swings (-40°C to 85°C), and gale-force winds. By prioritizing longevity, we cut lifetime O&M costs by 22% while delivering unwavering stability—critical for utility-scale farms and commercial installations where reliability translates to ROI.

Double-Sealed Defense: Pure Performance, Zero Contaminants

Moisture and particulates are silent killers of solar panel tracking efficiency. Antaisolar’s proprietary double-sealed driver structure creates an impenetrable barrier, ensuring internal components remain contaminant-free. Twin labyrinth seals block dust, sand, and humidity, while hydrophobic coatings repel water ingress. This dual-shield technology maintains optimal gear engagement and electrical conductivity, even in Saharan dust storms or monsoon-prone regions. The result? Consistent energy harvests without performance degradation.

Self-Sustaining Mechanics: Maintenance Made Obsolete

Labor-intensive lubrication cycles plague traditional trackers. Antaisolar redefines ease with self-lubricating bearings infused with polymer composites. These components autonomously release lubricants during operation, eliminating manual greasing for 10+ years. Field tests in Nevada’s arid terrain and Chilean salt flats confirm zero friction failures over 100,000 cycles. This innovation not only reduces technician site visits by 65% but also prevents environmental leaks—aligning with ISO 14001 sustainability benchmarks.

Corrosion Crushers: Materials That Endure

Antaisolar’s solar panel tracking systems leverage military-grade materials and nano-ceramic coating techniques. Each slew drive undergoes multi-layer passivation: zinc-nickel electroplating resists salt spray (per ASTM B117), while ceramic top-coats repel chemical corrosion from ammonia or sulfur pollutants. Rigorous IEC 60068-2-52 testing validates 20-year resistance against coastal humidity and industrial fallout. Our components exceed IEC 62817 standards, ensuring global compliance from California to the Gobi Desert.

Conclusion

Every Antaisolar solar panel tracking system embodies our ethos: Precision engineered, perpetually powered. With 5.2GW deployed across 37 countries, our solutions empower developers to maximize kWh yield while future-proofing investments. From self-maintaining mechanics to corrosion-defying builds, we turn environmental hurdles into opportunities. Partner with Antaisolar—where relentless sun meets relentless innovation.

end