Technical Considerations for Metal Roof Solar Mounting Systems

October 07, 2025

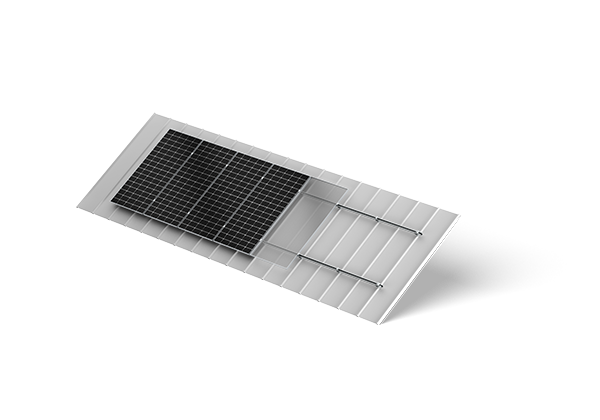

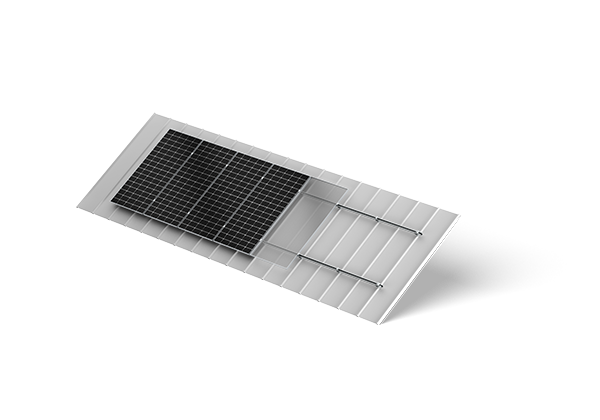

Metal roofs present distinct requirements for solar installations that demand specialized mounting approaches. The appropriate mounting solution must address roof profile variations, structural requirements, and installation efficiency while maintaining the building's weatherproofing integrity. Professional installers benefit from systems that adapt to different metal roof configurations while ensuring long-term reliability.

The engineering behind these mounting systems involves structural mechanics and material science considerations. Properly designed systems account for wind uplift forces, thermal expansion, and corrosion resistance while preserving the roof's waterproofing characteristics. These technical aspects directly affect system durability and investment returns.

Compatibility Across Metal Roof Profiles

Antaisolar metal roofs feature various profiles,including standing seam, trapezoidal, and Kliplok configurations, each requiring specific clamping solutions. Mounting systems should accommodate these variations through adaptable connection methods that prevent roof penetration. Clamping mechanisms must distribute load evenly across roof seams without affecting weatherproofing performance.

Material specification remains important for system compatibility. Aluminum alloy mounts provide favorable strength-to-weight ratios and natural corrosion resistance, while stainless steel components offer additional durability in coastal environments. Thermal expansion coefficients of mounting materials should align with those of the roof substrate to reduce stress during temperature changes.

Installation efficiency improves with pre-assembled components and standardized connection details. Systems that limit on-site fabrication decrease installation time and potential errors. Effective mounting solutions include clear engineering documentation that specifies torque values, load capacities, and installation sequences for different roof types.

Structural Performance and Long-Term Reliability

Solar mounting systems must endure environmental loads,including wind, snow, and seismic forces specific to project locations. Engineering calculations should address both downward gravity loads and upward wind lift forces, with appropriate safety factors based on local building codes. System structural performance depends on individual component strength and overall system integration.

Corrosion protection represents another important consideration. Aluminum systems typically use anodized or powder-coated finishes, while steel components require hot-dip galvanization or advanced coating systems. Electrochemical compatibility between different metals must be considered to prevent galvanic corrosion, particularly in challenging environments.

Maintenance accessibility and future roof servicing requirements should influence mounting system selection. Systems that permit panel removal and reinstallation support roof maintenance and repair operations. The design should also address thermal performance, ensuring sufficient airflow behind panels to prevent heat buildup that might affect solar efficiency and roof membrane durability.

Conclusion

Appropriate solar roof mounting systems installations require careful assessment of technical specifications and performance characteristics. The suitable solution balances structural requirements, material compatibility, and installation efficiency while maintaining roof integrity. Professional installers should prioritize systems with comprehensive engineering documentation and established performance history specific to metal roof applications. Technical support from manufacturers familiar with both solar requirements and roofing systems can offer valuable guidance for project-specific challenges.

The engineering behind these mounting systems involves structural mechanics and material science considerations. Properly designed systems account for wind uplift forces, thermal expansion, and corrosion resistance while preserving the roof's waterproofing characteristics. These technical aspects directly affect system durability and investment returns.

Compatibility Across Metal Roof Profiles

Antaisolar metal roofs feature various profiles,including standing seam, trapezoidal, and Kliplok configurations, each requiring specific clamping solutions. Mounting systems should accommodate these variations through adaptable connection methods that prevent roof penetration. Clamping mechanisms must distribute load evenly across roof seams without affecting weatherproofing performance.

Material specification remains important for system compatibility. Aluminum alloy mounts provide favorable strength-to-weight ratios and natural corrosion resistance, while stainless steel components offer additional durability in coastal environments. Thermal expansion coefficients of mounting materials should align with those of the roof substrate to reduce stress during temperature changes.

Installation efficiency improves with pre-assembled components and standardized connection details. Systems that limit on-site fabrication decrease installation time and potential errors. Effective mounting solutions include clear engineering documentation that specifies torque values, load capacities, and installation sequences for different roof types.

Structural Performance and Long-Term Reliability

Solar mounting systems must endure environmental loads,including wind, snow, and seismic forces specific to project locations. Engineering calculations should address both downward gravity loads and upward wind lift forces, with appropriate safety factors based on local building codes. System structural performance depends on individual component strength and overall system integration.

Corrosion protection represents another important consideration. Aluminum systems typically use anodized or powder-coated finishes, while steel components require hot-dip galvanization or advanced coating systems. Electrochemical compatibility between different metals must be considered to prevent galvanic corrosion, particularly in challenging environments.

Maintenance accessibility and future roof servicing requirements should influence mounting system selection. Systems that permit panel removal and reinstallation support roof maintenance and repair operations. The design should also address thermal performance, ensuring sufficient airflow behind panels to prevent heat buildup that might affect solar efficiency and roof membrane durability.

Conclusion

Appropriate solar roof mounting systems installations require careful assessment of technical specifications and performance characteristics. The suitable solution balances structural requirements, material compatibility, and installation efficiency while maintaining roof integrity. Professional installers should prioritize systems with comprehensive engineering documentation and established performance history specific to metal roof applications. Technical support from manufacturers familiar with both solar requirements and roofing systems can offer valuable guidance for project-specific challenges.

end